Products and Solutions

As a leader in the industry, the Maintek Group has established mutually beneficial strategic business partnerships and collaborations with like-minded key industry leaders to increase, widen and broaden its presence in the global world market and engineer great value for money to all esteemed clients in this space.

Empty Bottle Inspectors - Miho David 2

Complete inspection of empty bottles after the washer and before the filler: base, finish, thread, sidewall...

360° End-of-Line Inspection - Miho Allround

For a final quality inspection of filled and labelled containers by at least 4 cameras to ensure a 360 ° inspection.

Labels can be inspected for the following criteria:

Filling & Packaging Systems - RGB , P E T , C A N , K E G

Aquarex systems

An Aquarex is a multi-stage filtration system to clean soiled caustic & acid solutions. The system is comprised of:

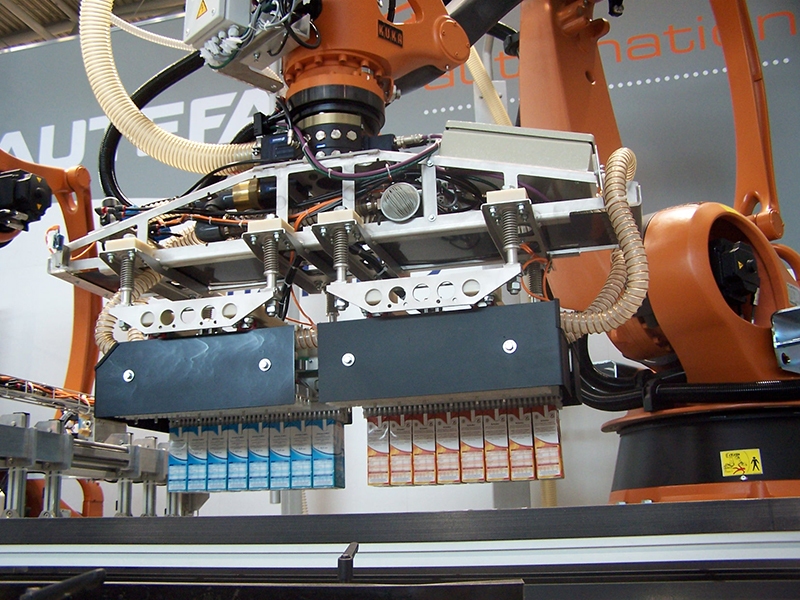

We have partnered with AUTEFA Solutions to provide the complete dry section for filling plants from raw material supply to fully automatic high bay storage systems with integrated transfer of goods to the dispatch area. According to the requirements, high-performance machines having several axes are used for packing, palletizing or stacking. Fully automatically adjustable gripper heads and infeeds streamline the process, amongst others by considerably reduced changeover times.

Fully Automatic Packer

The AUTEFA Solutions set-packer is used for packing and un-packing round, oval and square glass or plastic containers in crates, cartons with and without partition or in trays. Depending on the machine, capacities of up to 38,000 bph can be reached.

The format change can be done quickly by pressing the button and operating the panel depending on the requested automation level. That means that the change period can be reduced to a minimum and a very high operational availability can be achieved.

Fully automatic sorting installation

The AUTEFA Solutions fully automatic sorting installation has been developed for companies which produce products sort by sort and deliver it mixed in a carton or tray. The repacking process is working according to pre-selected mixing patterns. The automatic sorting installation enables the mixing of Tetra packs sizes from 0,2 l – 1,0 l. With special gripper systems also glass bottles and plastic containers can be handled. By means of exchangeable gripper heads arrangements of 2 x 6 / 2 x 8 / 3 x 9 can be created. The tracking of product data to customers ERP system can be included as well as the machine data recording.

All technology is by Autefa Solutions

Sweep-off Depalletizer

The AUTEFA Solutions sweep-off depalletizer type Certant R fixes and secures the bottle layers during every lifting and sweeping movement. Each bottle layer remains fixed by the centering frame until the sweep-off cycle is completed. Falling bottles are prevented before and during the sweep-off cycle. The sweep-off depalletizer of AUTEFA Solutions avoids broken glass in the dry area. Employees can concentrate on basic tasks and are not busy with removing broken glass. The risk of injury and contamination by broken glass is avoided.

Dairy, Food, Beverage and Personal Care Processing and Packaging Systems

ABMS and Maintek are collaborating companies. ABMS is in South Africa and Maintek is in Kenya. ABMS-Maintek have a vast experience on FMCG machinery and operations management systems ABMS and Maintek offer services that optimize complex processes. Our employees have experience of over 20 years in FMCG industry and service sectors. We are passionate about our services; working with us will give you maximum convenience and your business will be more effective and efficient. Our aim is to provide first class service.